发动机气缸压差测试仪E2A-12MM

适用Rotax、莱康明、continental等通用航空活塞发动机

The Differential Cylinder Pressure Testers quickly locate worn and cracked rings, defective intake and exhaust valves, scored and cracked cylinders, leaky head gaskets, and worn and stripped spark plug bushings; virtually every potential cause of pressure loss.

Model E2A Tester, for cylinders of less than a 5.00 inch bore* with a .040 inch diameter orifice that eliminates all guess-work by enabling you to determine the exact location and cause of your engine's efficiency loss. This tester is recommended by TCM per Service Bulletin SB03-3.

注:适用于直径小于5.00英寸汽缸,orifice孔径0.04英寸

Model E2A-12MM includes:

New Slow Fill ValveTM

Safely find TDC

Safely bleed cylinder test pressure to

zero for testing multiple cylinders

No repeated pressure adjustments

Features:

Heavy Duty Regulator

Heavy Duty Gauges

All Connections Quick-Disconnect

12 mm Plug Adapter

Extra Long High Pressure Hose

Complete instructions with each unit

(10/14 mm Adapter Available)

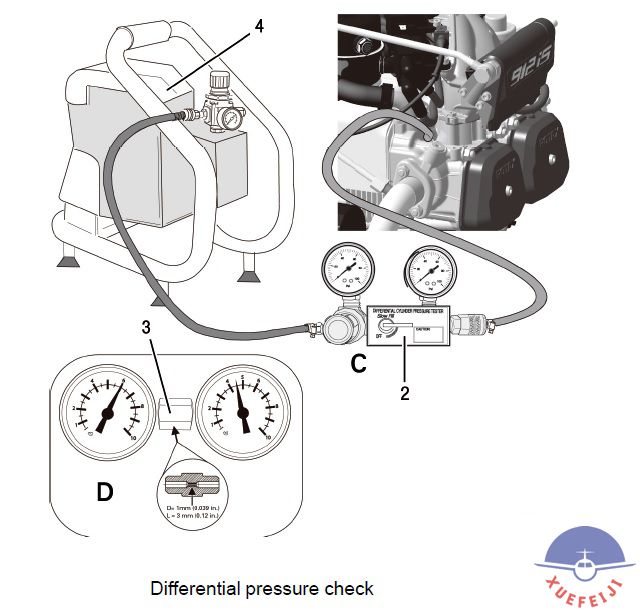

E2A Differential Cylinder Pressure Tester Instructions

Warning: This device is for use with aircraft by qualified A.P. Technicians only. All aircrafts tests should be performed by two technicians. Air pressure can cause the propeller to rotate suddenly and without warning. It is not possible for one individual to safely perform these tests on aircraft.

Setup:

If you are testing a certified aircraft engine, perform Master Orifice manufacturer's documentation for procedure.

Run engine until it reaches normal operating temperature. Remove the most accessible spark plug from each cylinder. Set the Slow Fill Valve to the Off position; handle vertical and pointing down.

After making sure the Slow Fill Valve is OFF, connect an air source to the tester, via the male quick connect fitting Air source must be at least 90 PSI.

Pull Pressure Regulator knob to unlock, and adjust so the left hand gauge reads 80psi.

Operation:

Hand tighten Test Adapter, with O Ring and hose, into cylinder under test

Place a thumb over the end of the hose fitting and rotate the prop until the piston's compression blows thumb off hose end. This will place the cylinder close to top dead center.

Connect the hose from the cylinder under test to the tester via the female quick connect fitting.

Slowly open the Slow Fill Valve approximarely l/8 Turn (3 or 4tick marks),until moderate resistance is felt at the prop. Carefully rotate the prop back and forth through TDC until a positive detent is felt and the air pressure holds the prop at TDC.

Warning:Cylinder pressure will slowly rise to 80psi,and prop may rotate. Exercise Caution!

Open the Slow Fill Valve completely; handle horizontal. parallel to the Pressurized Level.

If necessary, readjust the regulator to 80psi at the left hand gauge.

Read the relative pressure in the cylinder under test, at the right hand gauge.

To Test Another Cylinder

Set the Slow Fill Valve to the Off position, and allow the cylinder pressure to bleed off. The right hand gauge will slowly return to zero. There is no need to turn down there gulator pressure.

When the right hand gauge reads to zero, with the Slow Fill Valve still closed, remove the test hose from the female quick connector.

Remove the Test Adapter from the cylinder just tested, and hand tighten it into the next cylinder.

Repeat the OPERATION procedure, listed above

粤公网安备 44040302000324号

粤ICP备15064906号 Powered by Xuefeiji X1.0 Code ©2003-2020

粤公网安备 44040302000324号

粤ICP备15064906号 Powered by Xuefeiji X1.0 Code ©2003-2020