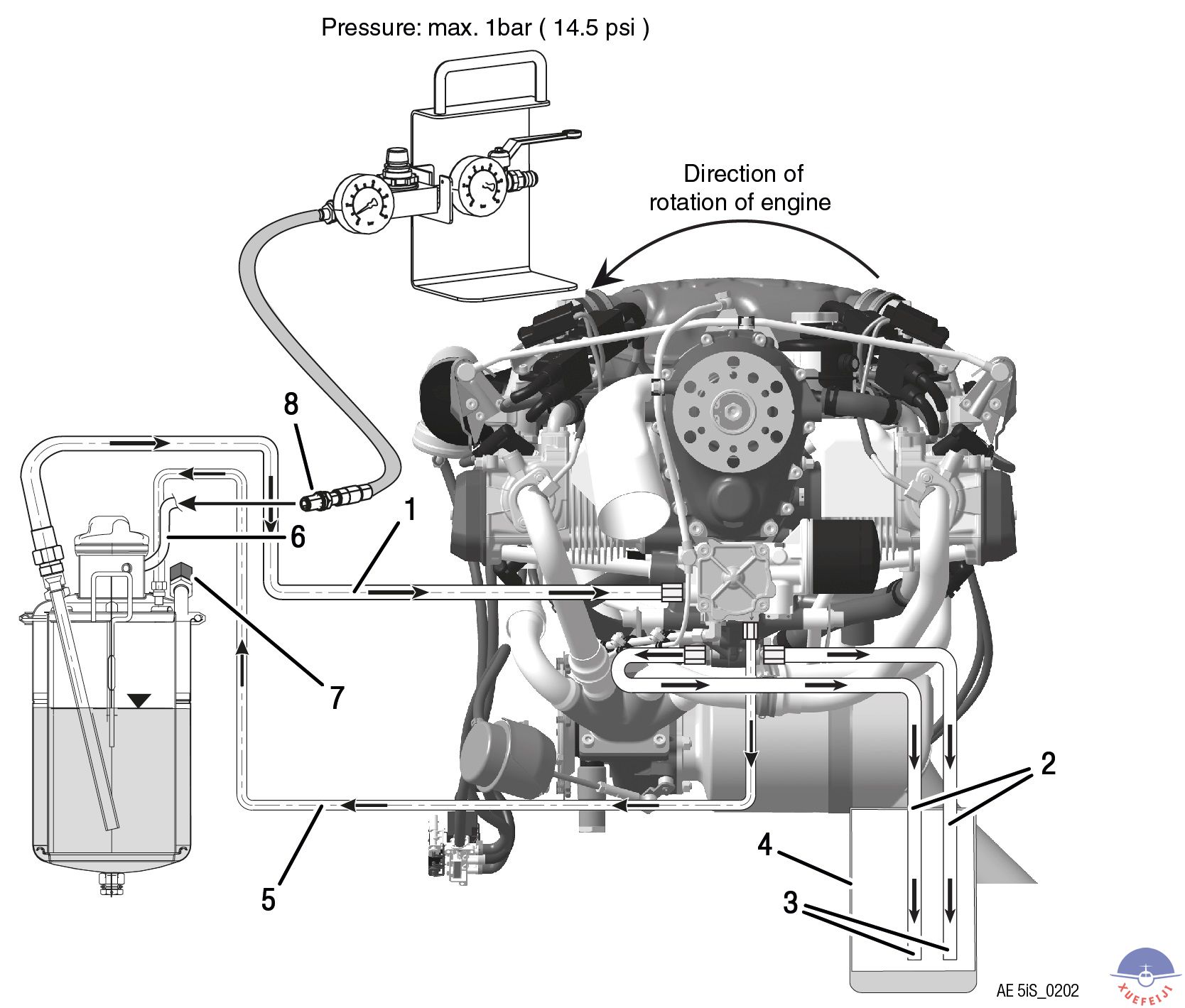

滑油系统清洗和加注FILLING AND PURGING OF THE OIL SYSTEM

The following work procedures must be carried out for purging the oil system:

1. Disconnect oil return lines (2) from the oil tank.从油箱上断开回油管(2)

2. Place the free end of the return lines into a suitable container (4) below the engine.

3. Plug open connections on oil tank with suitable air tight cap.

4. Remove the spark plug connections.

5. For easier rotation of engine remove one spark plug from each cylinder.

6. Using a compressed air line, pressurize the oil tank through its vent fitting (6) (on the neck of the tank). Adjust the compressor outlet regulator so that the air line pressure is between 0.4 bar (5.8 psi) and 1 bar (14.5 psi). Do not exceed 1 bar (14.5 psi).

7. Turn the engine by hand in direction of normal rotation until the first pressure indication ap- pears on the oil pressure gauge. Normally this will take approx. 20 turns. Depending on in- stallation it may take up to 60 turns.

NOTE

The oil tank may empty and as a result introduce air into the oil system. Pay atten- tion to the oil level and fill tank as required.

8. Stop the pressurization.

9. Open the cap for the oil return lines on the oil tank and reconnect the engine oil return lines to the tank. Ensure that the suction oil line and oil return line are connected to proper fittings on the oil tank. Note: If the oil lines from engine to oil tank are incorrectly connected, severe engine damage may result.

10. Re-fit the spark plugs. Restore aircraft to original operating condition.

11. Residual oil may have accumulated in the crankcase. Return it to the oil tank by following the oil level check procedure in the relevant Operators Manual (OM).

12.Fill the oil in the tank up to the full mark on the dipstick.

13. Carefully check all lubrication system connections, lines and clamps for leaks and tightness.

1 Suction line2 Oil return line

3 Free end 4 Temporary oil collection tank

5 Oil return line 6 Vent fitting

7 Plug (2x) 8 Temporary connection for purging

粤公网安备 44040302000324号

粤ICP备15064906号 Powered by Xuefeiji X1.0 Code ©2003-2020

粤公网安备 44040302000324号

粤ICP备15064906号 Powered by Xuefeiji X1.0 Code ©2003-2020