Preparation:

Before the propeller gearbox is removed, the work described below must be carried out to identify any further malfunctions:

- General visual inspection, see current Maintenance Manual Line (MML) for the respective engine type.

NOTE: Particular attention is needed in the corresponding zone of the crankcase and gear- box mounting screw holes, including the dowels. If any cracks/abnormalities are found, the engine must be shipped to any Rotax approved overhaul facility for repair/ overhaul.

- Remove the surrounding assemblies, see current airframe and propeller manufacturer’s

instructions.

- Remove the gearbox oil line assy, if installed.

-Remove the external alternator, if installed.

Step | Procedure |

1 | Remove the gearbox and drive gear. See current Maintenance Manual Line (MML) for the respective engine type. |

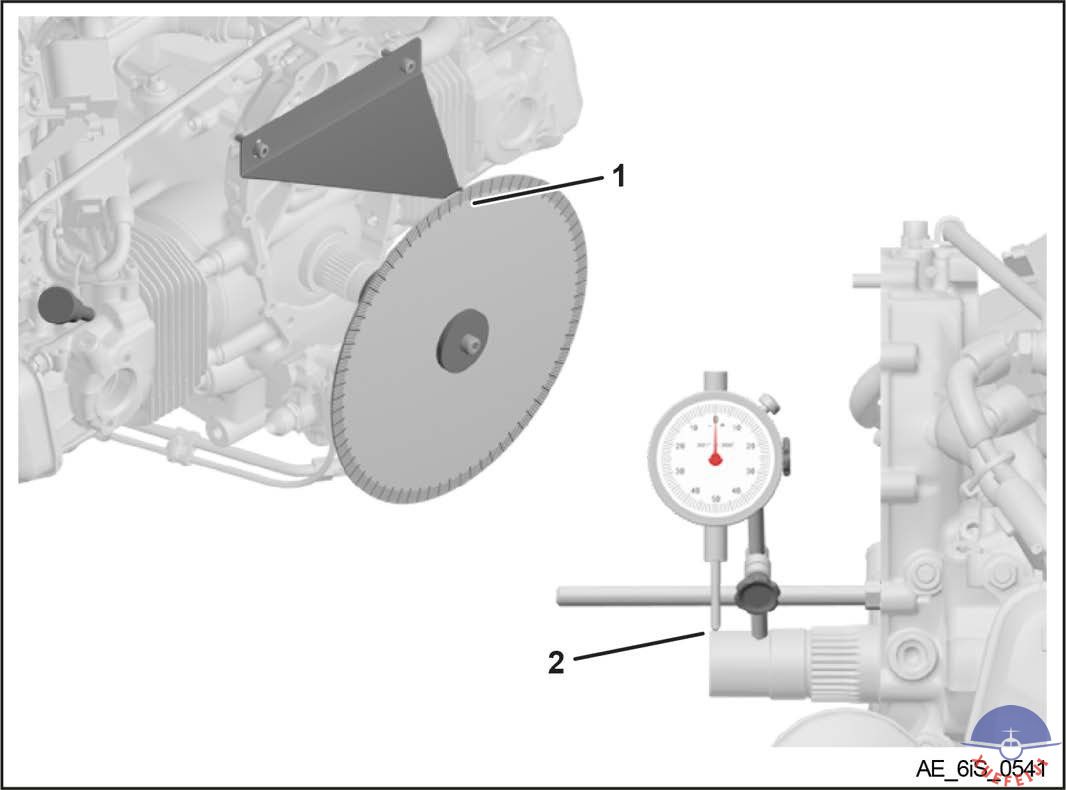

2 | Perform a crankshaft run-out inspection on the PTO side. See current Maintenance Manual Heavy (MMH) Chapter72-10-00 for the respective engine type. |

3 | Perform a crankshaft distortion inspection. See current Maintenance Manual Heavy (MMH) Chapter 72-00-00 for the respective engine type. |

4 | If any of the above measurements are exceeded, the engine needs to be shipped to any Rotax approved overhaul facility for repair/overhaul. |

5 | If the above measurements are within limits, perform service of the whole gearbox in accordance with current Maintenance Manual Heavy (MMH) Chapter 72-10-00 for the respective engine type. |

Step | Procedure |

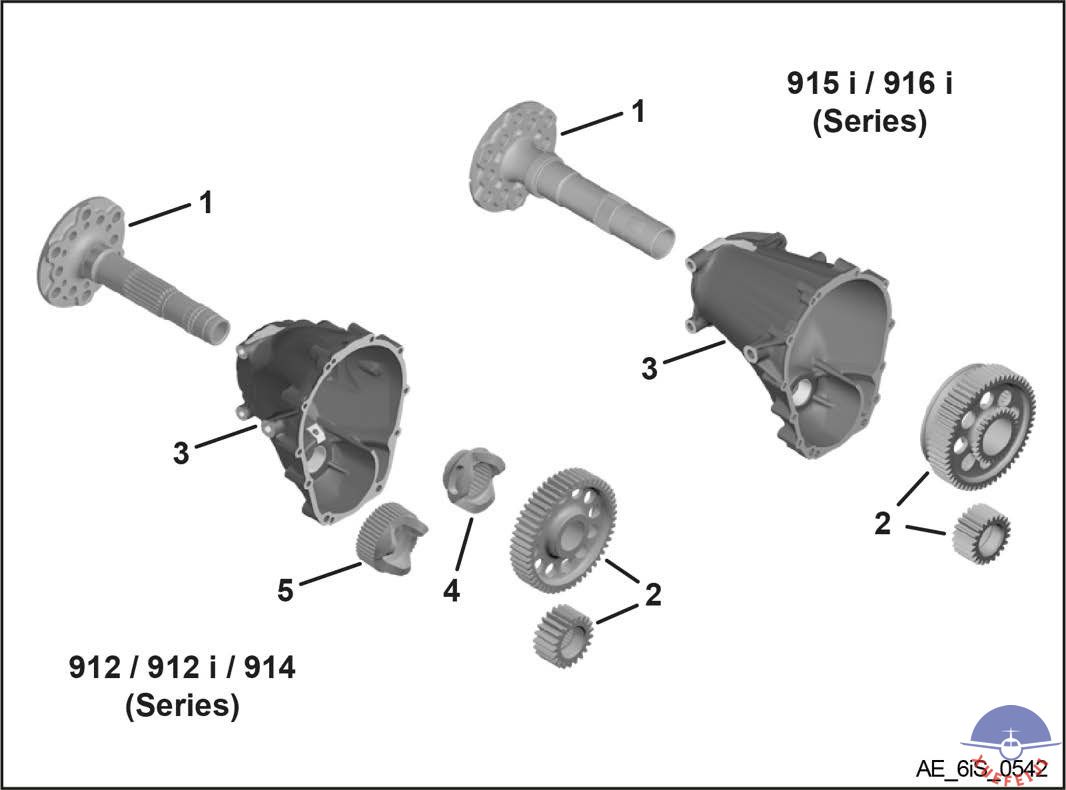

6 | Perform NDT inspection of the propeller shaft (1), gear set (2) and gearbox housing (3). For 912, 912 i and 914 (series), also perform NDT inspection of the dog hub (4) or clutch hub (5). NOTE: In the case of 912 i, 915 i and 916 i engine series, the gearbox housing has an electrophoretic coating (black) that does not require removal in order to perform the crack detection. |

7 | If cracks are detected on any of these components the parts need to be replaced. NOTE: The gearbox mounting screw holes, dowel holes and roller bearing fixa- tion screw holes must be carefully inspected for any cracks or abnormal- ities. |

1 Propeller shaft

2 Gear set

3 Gearbox housing

4 Dog hub

5 Clutch hub

Step | Procedure |

8 | Disassemble overload clutch and damper clutch. See Chapter 72-10-00 Maintenance Manual Heavy (MMH). NOTE: The overload clutch of the 912, 914 and 912i Series, needs to be shipped to any Rotax approved overhaul facility for repair/overhaul. |

9 | Check all given wear limits for the gearbox assy. See current Maintenance Manual Heavy (MMH) Chapter 72-10-00 of the respective engine type section “Inspection” and “Wear Limits”. |

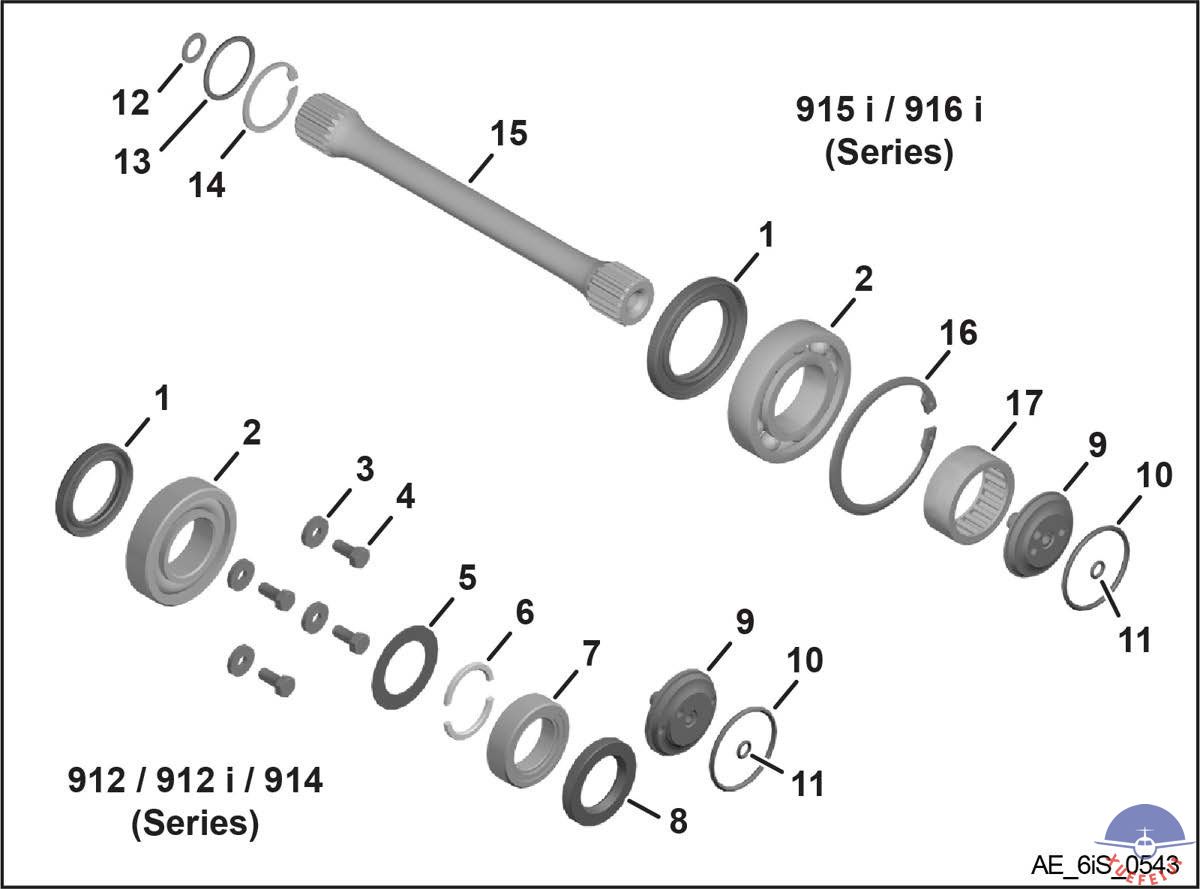

10 | Replace all 100% replacement parts in accordance with current Maintenance Manual Line (MML) chapter 05-50-00, for the respective engine type. |

1Oil seal

2 Ball bearing

3 Washer

4 Hex screw

5 Thrust washer

6 Ring half (x2)

7 Roller bearing

8 Oil seal

9 Oil inlet flange 10 O-ring

11 O-ring

12 Sealing ring

13 O-ring

14 Retaining ring

15 Torsion shaft

16 Retaining ring

17Needle bearing

Step | Procedure |

11 | If the rest of the parts are not within given limits or have unusual wear or damage, the parts need to be replaced. |

12 | Assemble gearbox. See current Maintenance Manual Heavy (MMH) Chapter 72-10- 00 of the respective engine type, section “Assembly”. |

13 | Re-install drive gear in accordance with current Maintenance Manual Line (MML) chapter 05-50-00, for the respective engine type. Check the crankshaft run-out. See current Maintenance Manual Heavy (MMH) Chapter 72-10-00 for the respective engine type. |

14 | Re-install the gearbox in accordance with current Maintenance Manual Line (MML) chapter 05-50-00 for the respective engine type. |

Finishing work:

- Install the gearbox oil line assy, if installed.

- Install the external alternator, if installed.

-Install the surrounding assemblies, see current airframe and propeller manufacturer’s instruc- tions.

粤公网安备 44040302000324号

粤ICP备15064906号 Powered by Xuefeiji X1.0 Code ©2003-2020

粤公网安备 44040302000324号

粤ICP备15064906号 Powered by Xuefeiji X1.0 Code ©2003-2020